Welding is dangerous. That’s why it’s important to protect yourself from all the potential hazards that could come your way. From intense heat to harmful dust, your work environment demands top-tier safety measures. Most welders are equipped with helmets and gloves, so why is respiratory protection often overlooked?

Optrel is committed to empowering welders with the best protection, not just for their eyes but also for their lungs. Protecting your lungs isn’t about compliance; it’s about safeguarding your health and ensuring you can continue to do what you love for years to come.

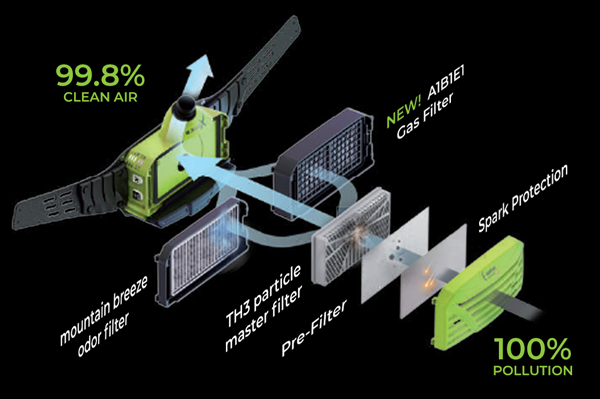

Powered Air Purifying Respirators (PAPRs) are like a breath of fresh air in the world of welding safety gear. These devices use a fan to draw in air, which is then filtered before being delivered to you.

PAPRs are crucial for welders because they protect against harmful fumes and gases. They ensure that welders can work safely and comfortably, even in environments with elevated levels of contaminants. Plus, they’re often more comfortable to wear than traditional respirators, making them a popular choice among welders looking for both protection and comfort.

Not wearing a Powered Air Purifying Respirator (PAPR) in welding is like playing with fire, literally! Welding produces a cocktail of dangerous fumes. Without proper protection, you’re exposing yourself to risks like metal fume fever, respiratory issues, and even long-term lung damage.

Welding creates toxins that, if inhaled, can pose serious health risks. From metal oxides to harmful gases like ozone and nitrogen dioxide to toxins like hexavalent chromium, the welding environment can be hazardous to respiratory health.

Hexavalent chromium, or hexchrome, poses a severe danger to welders. Hexchrome is produced as a byproduct when chromium in metal alloys is heated to high temperatures. If inhaled, it can lead to issues like asthma and lung cancer, even at low concentrations. A carcinogen, around 558,000 workers in the United States are exposed hexchrome, welding being the industry with the highest reported exposure.

Prolonged exposure to these airborne contaminants can lead to many unwanted illnesses. Acute exposure can cause irritation of the eyes, nose, and throat, as well as dizziness and nausea. It’s crucial for welders to protect themselves from these hazards to ensure their long-term health and well-being.

Welding might make you feel like a superhero with a torch, but the fumes can be your kryptonite. If you want to keep your lungs in top shape and keep welding like a pro, make sure you’re protecting yourself with the right gear. Your lungs will thank you.

PAPRs are recommended for welders and other workers exposed to hazardous fumes, gases, or particulates in their work environment. This includes industries such as:

PAPRs are especially beneficial in situations where traditional respirators may not provide adequate protection, such as environments with high levels of contaminants or prolonged exposure to hazardous substances.

It is important to note that PAPRs purify the air, but don’t directly supply you with oxygen, so they should never be used in environments with low oxygen levels. If your occupation encounters lots of dust, fumes, and other airborne contaminants, it’s crucial to consider using a PAPR for respiratory protection.

Employers are required to provide information and training on hazardous materials in the workplace, and welders should take advantage of this training to understand how to protect themselves. Cleaning welding surfaces of any coatings that could create toxic exposure, positioning themselves to avoid breathing toxic fumes, and using general ventilation or local exhaust ventilation systems are all important steps in reducing exposure.

Your ideal respiratory choice depends on several factors, including:

For those interested in creating their own PAPR system, check out this guide for step-by-step instructions. Remember, proper respiratory protection is key to ensuring your long-term health and well-being.

So how is a PAPR different from the N95s or DIY cloth masks that we grew all so familiar with? There’s actually a big difference and wearing the wrong mask could set you up to be exposed to countless harmful toxins.

PAPRs rely on battery power to pass air through the tubes into the wearers breathing zones, supplying you with a constant flow of filtered air, therefore heavily reducing airborne contaminants. Constant airflow prevents heat-buildup and moisture and provides the strongest protection against harmful welding gases.

N95 masks filter out around 95% of airborne particles but rely on your ability to create a seal against your face to ensure that all the air passes through the filter. Unlike PAPRs, N95 masks are disposable, and are more common to protect against respiratory infections.

Despite the initial higher cost compared to traditional respirators, investing in a PAPR offers long-term benefits that make it a cost-effective choice for welders. PAPRs are reusable and require minimal maintenance, reducing the overall cost of ownership while ensuring continuous protection for your respiratory health. PAPRs offer superior protection, comfort, and convenience compared to other types of masks, making them the preferred choice for welders.

Constantly evolving, PAPR technology offers better protection and comfort than ever before. In recent years, we have seen advancements in:

Advancements in welding PAPR technology are a game-changer for welders, offering enhanced protection and comfort in a hazardous work environment. Modern PAPRs ensure uninterrupted, high-quality respiratory protection, allowing you to focus on your craft without worrying about your safety. Progress in ergonomics makes wearing a PAPR more comfortable than ever, reducing fatigue during long welding sessions. Stay ahead of the curve with the latest PAPR technology and weld with confidence.

At Optrel, we continue to provide innovative products and we’re constantly striving to develop new and improved respiratory protection solutions to keep you safe and comfortable.

By prioritizing your respiratory health and choosing the right equipment, you can focus on what truly matters: the craft of welding. Your lungs are irreplaceable so choose the right respiratory protection to ensure you can breathe easy and weld with confidence.