Optrel cares! Eyesight is something we think about constantly at optrel. We have devoted countless hours and continue to innovate in order to improve the welder’s view. To show how serious we are about eyesight, in 2019, we partnered with Light for the World to help fund 3,000 restorative eye surgeries around the world. When we aren’t pledging to help cure blindness, we are preventing blindness and protecting the eyesight of our fellow welders.

The patented optrel ShadeTronic® technology automatically adjusts the shade level to the changing light conditions of the welding arc as you weld. This allows welders to work without interruption, with the perfect shade level, increasing productivity while eliminating eye strain and fatigue. Our technology does this by continuously measuring the light intensity of the welding arc using 5-point detection. Imagine never having to adjust your shade levels manually again!

Take the Panoramaxx series for example. The optrel 5-point detection integrated in the Panoramaxx series uses sophisticated software and clever positioning of four sensors at the corners and one sensor in the upper center to ensure the auto-darkening filter is switched on and off perfectly, even in the most difficult lighting conditions and in constrained positions, as well as permanent dark level adjustment during welding.

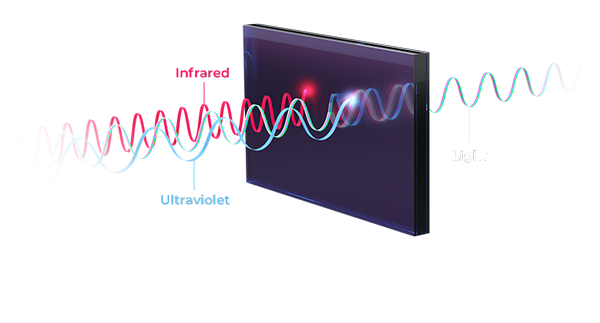

There are three types of light that can harm you while welding: Visible light, Infrared Light, and Ultraviolet light (UV). Visible light is light that can be seen with the human eye which can harm you with pure brightness. Infrared light shares the same spectrum as visible light but goes far beyond it into the realm of light that can’t be seen with the human eyes without help from technology. As NASA scientist put it, “People encounter Infrared waves every day; the human eye cannot see it, but humans can detect it as heat.” People also encounter UV rays daily from the sun, but welders also encounter them from arcs and metal surfaces while welding. UV rays destroy cell tissue.

To protect welders from these harmful lights, helmets are fitted with special darkening lenses that filter out the amount of light based on the shade level of the lens. The higher the shade number the more harmful light is excluded from a welder’s view. On the other hand, the darker the shade the harder it is to see what you are doing when the helmet is down. For that reason, many welders that use passive welding helmets will often leave their hoods up while not in use. The common danger of having your hood up too often is being “flashed” by an arc. You might be thinking you will never forget to put your hood down before striking an arc, but if you’re working with a team you must remember that people around you will be striking arcs too.

optrel helmets give you the best of both worlds. With an optrel lid you can have a lens with a low shade that allows you to keep your helmet down while you are not welding and see your work area. When you, or someone near you, strikes an arc our patented ShadeTronic technology will protect your eyes in under 1/100th of a millisecond to not only protect you from flashing, but can be adjusted to a shade that will allow you to move around freely.

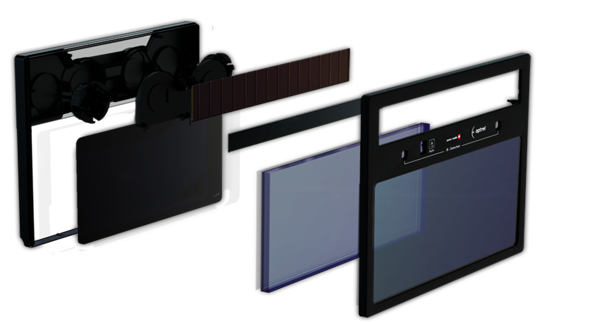

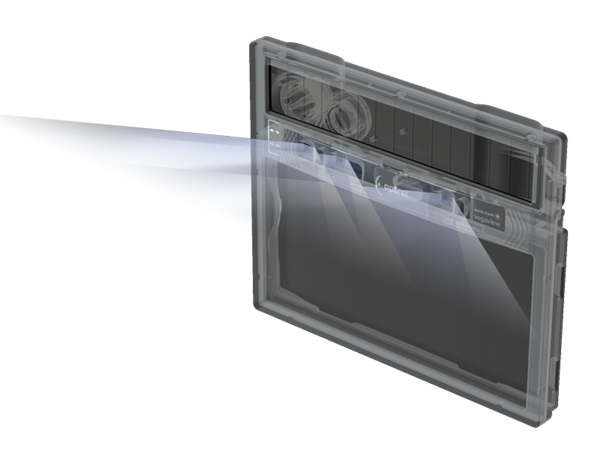

Although our helmets might feel like magic to the welders who wear them, we have advanced technology that goes into each optrel product. Our ADF, or automatic darkening filter, consists of liquid crystal displays (LCDs), electronic components, solar cells/batteries, sensors and a UV/IR filter. During certification, the quality of an ADF is assessed in line with the European standard graded over four key criteria: optical class, scattered light, homogeneity and dependence on angle of vision. All ratings must be stated on the darkening filter: 1 is the highest rating and 3 the lowest. Here is how each component works.

LCDs, amongst other things, contain liquid crystals which allow for automatic darkening of the filter. The arrangement of the liquid crystals is controlled by electric pulses. We then ad a UV/IR filter. This filter is used to reliably reflect optical radiation in the UV and IR range, keeping you safe from the risks we described earlier. Take note that our UV/IR filters are permanently fitted in the ADF and offers permanent protection regardless of whether the darkening filter is in the dark or light state. That is when our sensors come in. Sensors are fitted in the ADF detect when an arc is struck. When this happens, the sensors transmit a signal to the electronics which then activate the LCDs.

How is this all powered you ask? The power needed to operate the ADF can be guaranteed over different types of power supplies. For all expert- and pro-helmets, the power during welding comes from the solar cells, which generate energy out of the welding arc. However, to start the welding helmet the first time for each welding session, a backup battery is also included. For all optrel helmets, there is no need to switch it on or off.

Finally, we add two more covers, front and back, to protect this investment and keep it working for years. To prevent weld spatter from reaching and damaging the darkening filter the front cover lens is fitted on the helmet in front of the darkening filter. Depending on the welding process and dirt levels, the front cover lens must be replaced on a regular basis. On the other side, an inside cover lens is used to protect the back of the ADF from dust and other dirt. This thin plastic lens is a wearing part and can be replaced when it becomes dirty and discolored.

Enabling welders to have a better day-to-day work life, while also caring for them when they hang-up their helmet, is an everyday pursuit for optrel. Thousands have put their trust in our ShadeTronic technology and we will continue innovating for each and every one of them. If you find yourself wanting to put our helmets to the test you can see where to buy optrel near you. And if you really want to see the best, we have to offer check out our Panoramxx CLT. Optrel’s Shadetronic technology working in unison with the CLT 2.0 technology is already a seamless experience that will seriously make your job easier but add them together with the one of a kind Panoramxx view and you won’t believe your eyes.